Wastewater treatment in metalworking and processing

Recycle cooling lubricants – reduce disposal costs

Machining processes generate large quantities of used cooling lubricant emulsions and oil-containing process water. Disposing of these is not only expensive, but also poses an ecological challenge. With atmospheric evaporator solutions , you can reduce the amount of wastewater to be disposed of by up to 95% and lower your disposal costs by the same amount. Our complete systems offer a compact, reliable, and economical solution—tailored to the requirements of your manufacturing operation.

Reliable. Flexible. Safe to operate.

In addition to the actual distillation process, depending on the composition of the wastewater, a mechanical pretreatment can be integrated—for example, to separate chips and sludge . The purified distillate is clear, oil-free, and can be used for the preparation of cooling lubricants or for parts cleaning.

Depending on the composition of the wastewater, we combine evaporation with:

- pH adjustment

- Filtration via bag filters or belt filters

- Oil separation

- Downstream light phase separator

- Discharge monitoring (e.g., pH, temperature)

This gives you a stable, low-maintenance system with a high degree of automation—designed for continuous operation in an industrial environment.

Your advantages at a glance

Up to 95% less wastewater & Disposal costs

Reuse of purified water in operation

Selection of the right process technology based on in-house laboratory tests

integrated pretreatment

Customized design based on your needs

Areas of application

Typical wastewater in metalworking

- Used cooling lubricant emulsions

- Industrial washing and cleaning water

- Die casting emulsions

- Floor mopping wastewater

Optimize processes efficiently and sustainably

Would you like to make your production more efficient and environmentally friendly?

We will show you how MKR technology can help you treat your wastewater safely while minimizing costs, waste, and risk.

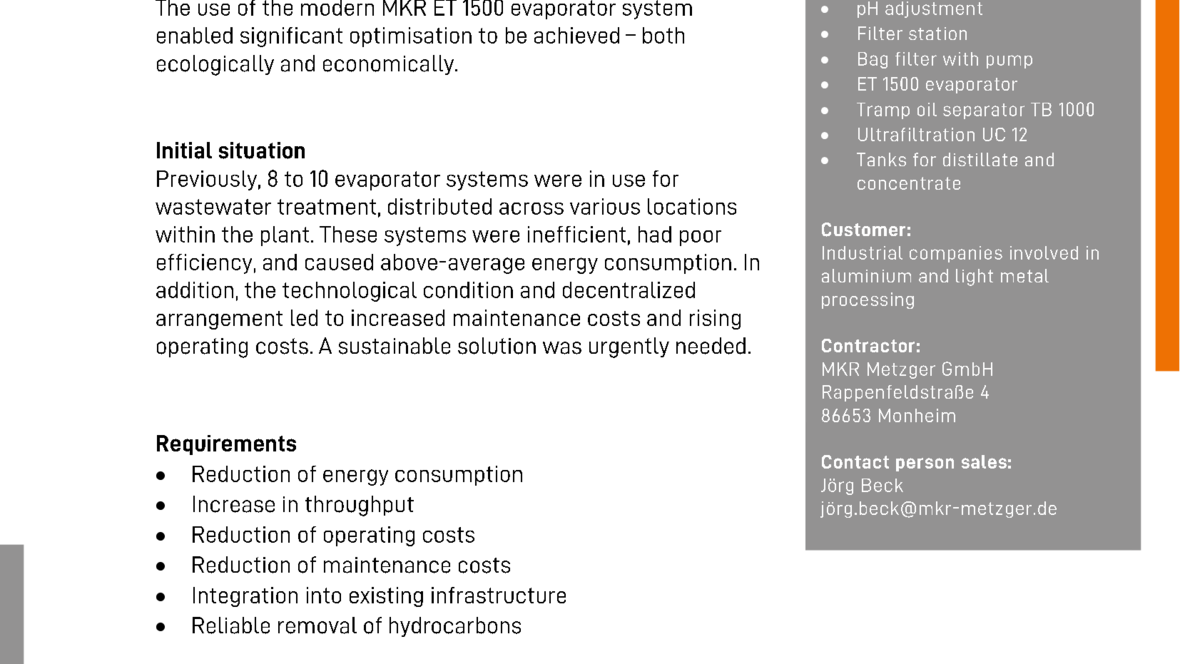

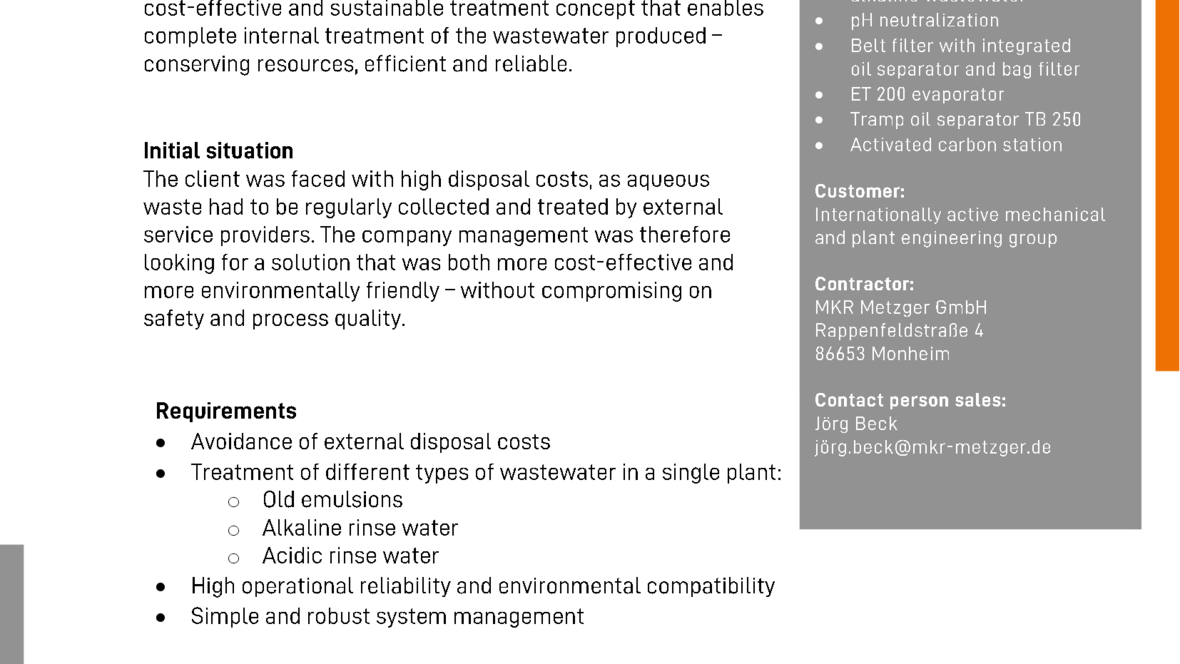

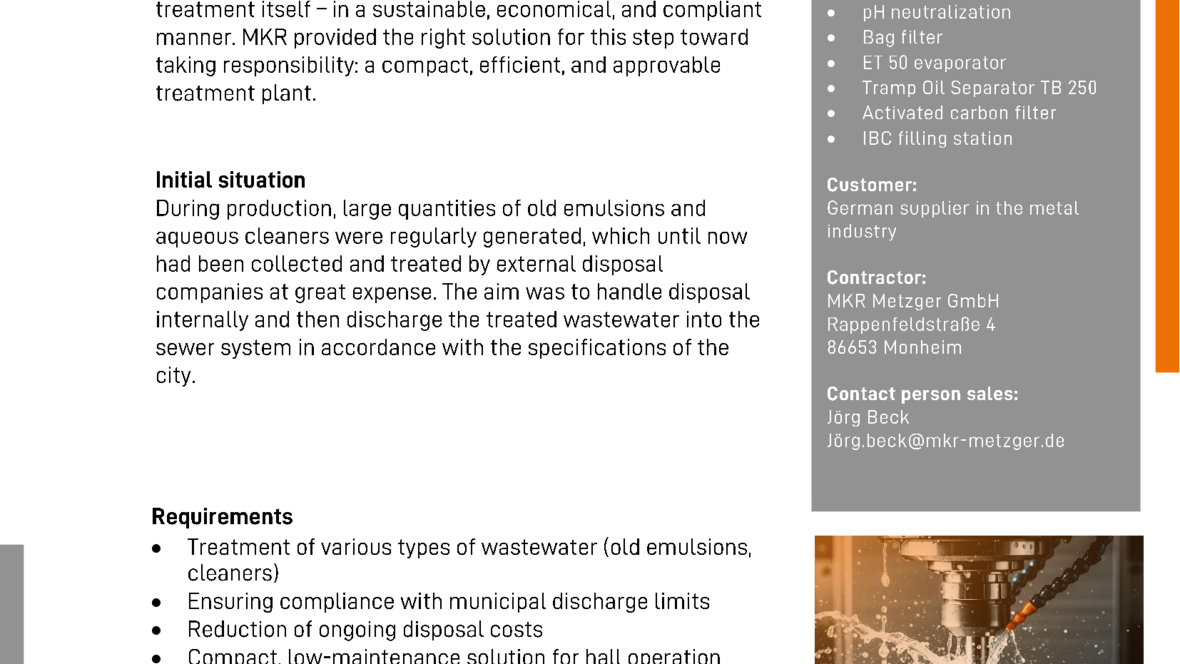

CASESTUDY - OLD EMULSIONS/ALKALINE AND ACIDIC RINSE WATER

Frequently asked questions

Our Evaporator systems

Maximum energy efficiency through mechanical vapor compression: Our fully automatic evaporators consume only 35 Wh/liter. Recover hygienized distillate of the highest quality for direct reuse in your production.

Our ultrafiltration systems

Our UC series uses purely mechanical ultrafiltration to separate particles, oils, and emulsions—completely without chemicals. Extend the service life of your cleaning baths many times over and ensure the consistently high quality of your process fluids.