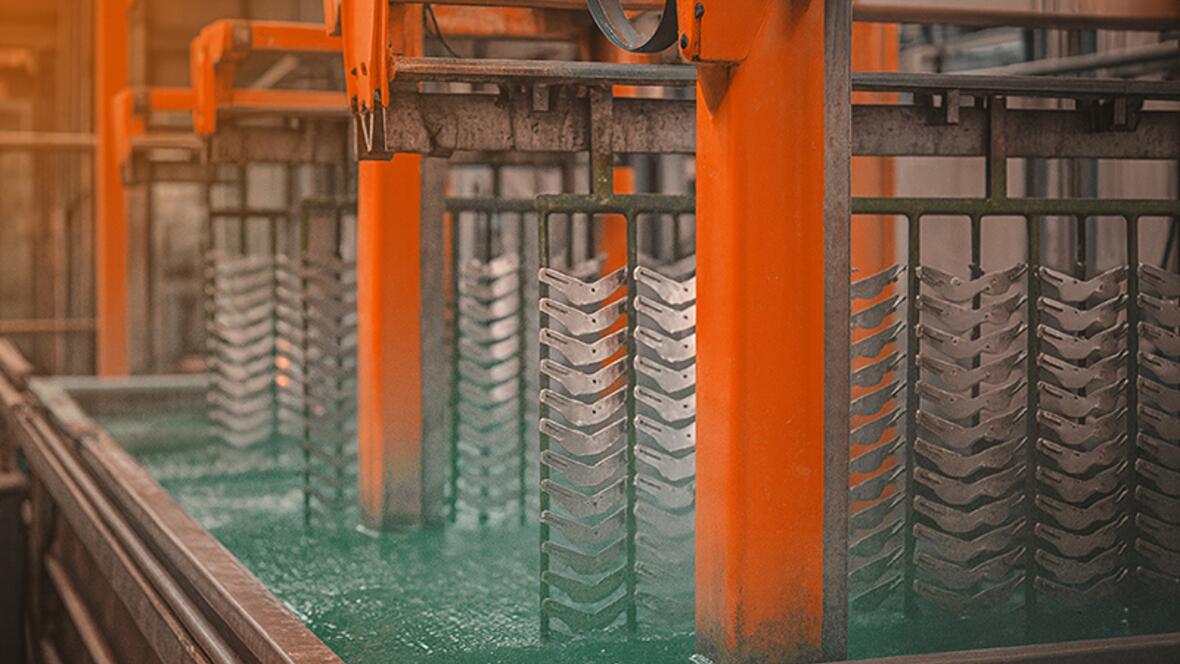

Safe separation of heavy metals and complexing agents in electroplating

Electroplating companies produce large quantities of rinse and process water every day, which is contaminated with heavy metals, acids, alkalis, or complexing agents. Reliable treatment of this water is not only necessary from an environmental perspective, but also makes economic sense—especially in view of increasingly strict legal discharge limits.

With our atmospheric evaporators , we offer a proven, chemical-free solution that can be used to treat even demanding wastewater safely and efficiently – without expensive precipitating agents or complex chemical-physical processes.

Your security during government audits

Unexpected inspections by environmental authorities are not uncommon in electroplating plants. Exceeding nickel, zinc, or copper limits can quickly lead to production shutdowns or fines. Our evaporation systems ensure that you achieve consistently stable discharge limits – regardless of fluctuating wastewater composition.

atmospheric vaporization technology

's targeted evaporation of process water under atmospheric pressure allows heavy metals, complexes, and pollutants to be reliably retained in the concentrate , while the resulting distillate is virtually free of harmful components. For you, this means:

• High operational reliability with changing wastewater compositions

• Cost-efficient operation thanks to automatic control and easy maintenance

Customized solutions for your electroplating

Every electroplating process is different – from small-scale coating to fully automated production lines. MKR designs each system to be tailor-made for your business, based on:

- Type of electrolytes used

- Process sequence (rinsing, activation, pickling, etc.)

- Space requirements and wastewater volume

- Discharge specifications and reuse options

Your advantages at a glance

High operational reliability – discharge values are consistently maintained

Minimized residue – easier to dispose of or further process

Significant reduction in wastewater volume

Reuse of purified water possible

Reuse of water purified by the

Proven technology, individually tailored to your requirements

Areas of application

Typical wastewater types in electroplating

- Rinse water from zinc and nickel processes (e.g., sulfamate, Watts)

- Rinse water from silver and copper electrolytes

- Baths containing cyanide and chromium (including detoxification)

- Acidic media from stainless steel pickling or degreasing

Optimize processes efficiently and sustainably

Do you operate an electroplating or surface treatment facility?

MKR is your experienced partner for the treatment of electroplating wastewater—with solutions that work in the long term.

Frequently asked questions

Our Evaporator systems

Unsere Verdampferanlagen

Maximum energy efficiency through mechanical vapor compression: Our fully automatic evaporators consume only 35 Wh/liter. Recover hygienized distillate of the highest quality for direct reuse in your production.

Our ultrafiltration systems

Our UC series uses purely mechanical ultrafiltration to separate particles, oils, and emulsions—completely without chemicals. Extend the service life of your cleaning baths many times over and ensure the consistently high quality of your process fluids.